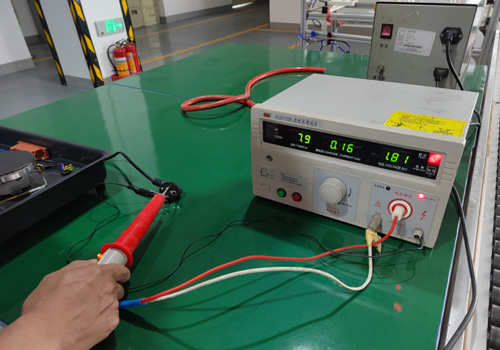

Withstanding Voltage Test

This machine is used to check whether the insulation ability of products under transient high pressure is qualified or not and detect defects in the product.

This machine is used to check whether the insulation ability of products under transient high pressure is qualified or not and detect defects in the product.

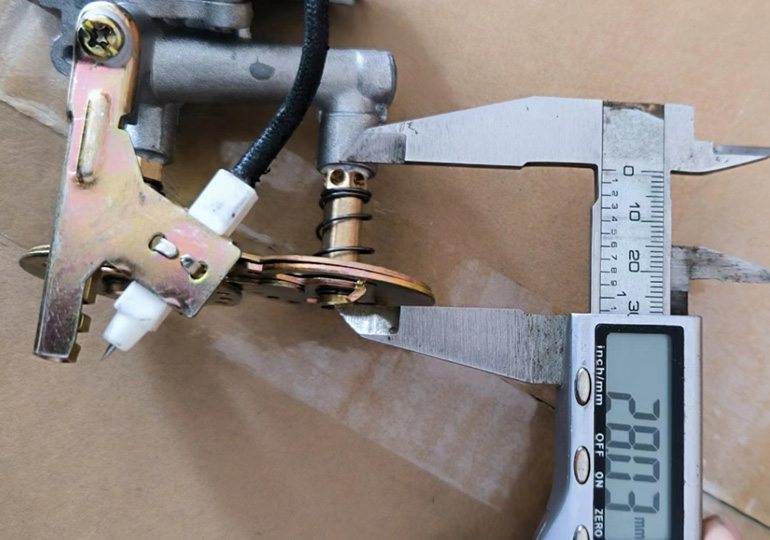

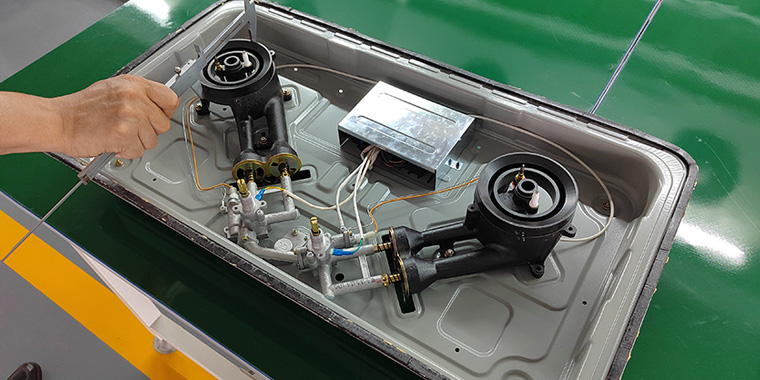

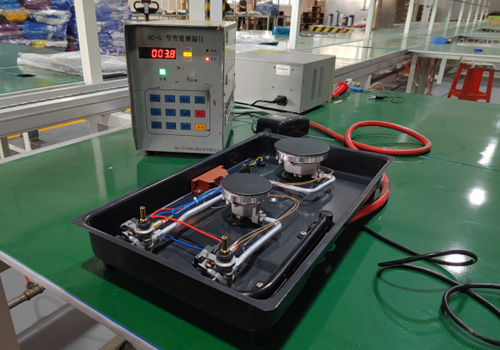

We have a machine that is able to find very slight gas leakage for the ignition and gas pipe.

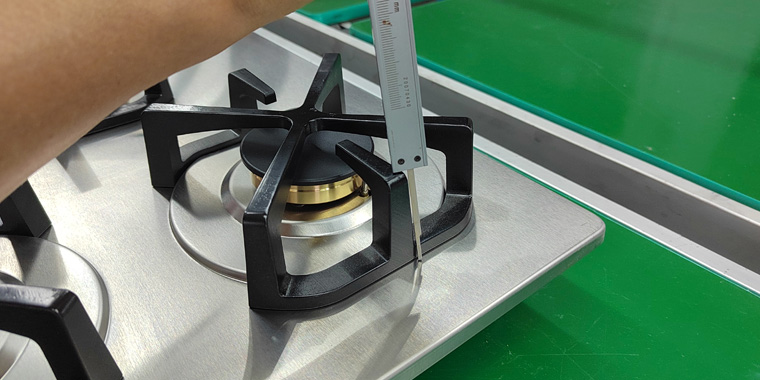

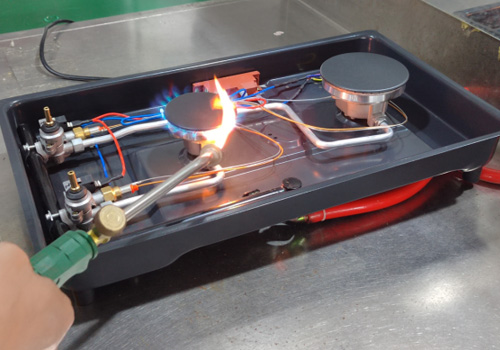

The visible flame testing can detect not only the gas leakage from the ignition valve and gas pipe, but also the safety for burner and burner cap.